So I’m installing a wardrobe with sliding doors here by the entrance. It will pretty much cover the whole wall that you see in the picture. Normally you could make a relatively simple wall on the left side of the sliding doors but since the whole apartment is torn down already, I’m throwing out the old floor and are going to build a thicker wall mounted to the concrete.

I found some old vinyl carpet under the laminated floor which was pretty nasty. And its leaving glue residues all over the concrete which I’ll probably try to remove with sanding later.

I guess it will be a good idea to use a respirator when tearing up the rest of the old flooring. Who knows what’s in that old dust. That was tip #1 for you guys.

Also make sure you know where to throw away the refuse when doing things like this. It always makes a lot more than you think.

Moving on..

The plan is to make the wall the same thickness and depth as the existing wall on the right.

It’s 7 cm (2 3/4″) and I plan to use MDF boards as the outer layer so with 45/45 studs (1 3/4″) and a layer of 13mm (½”) MDF on either side I should end up with 13+45+13=71 mm which is close enough. Depth will be 75 cm leaving about 65 cm (a bit over 2 feet) as the inside depth of the wardrobe.

In this sketch I experimented with including a ventilation hole in the wall which I will probably make smaller and place near the roof instead.

But let’s ignore the hole for now. At least you get the idea of the construction.

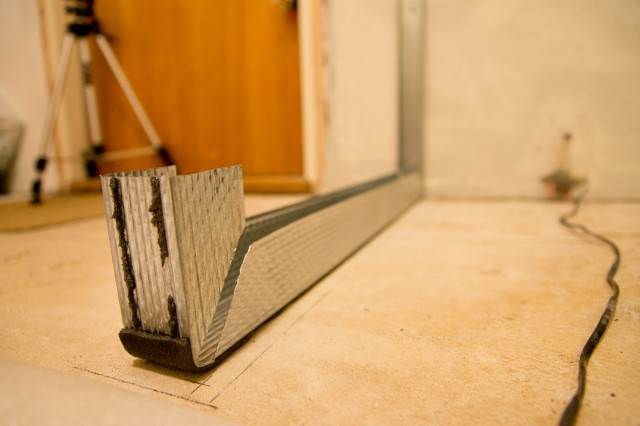

The steel rail is perhaps a bit overkill but the point is to not mount the wood studs directly to the concrete floor. The relative humidity may destroy the wood. Now I don’t think this would be an issue here but if the concrete slab would be directly on the ground it would be too humid.

I have ordered the doors to fit in an 186 cm wide opening so that’s my reference.

So I know the opening has to be 186 cm and I want the new wall to be square to the back wall. And that’s actually the only thing I have to care about but why not check all of the measurement while at it.

If you measure 186 cm along both the back edge and the front edge (in my case 75 cm out from the back wall at both ends) and mark them down on the floor you can then check both the the diagonal measurements (like a cross). If they are equal to one another you not only got a square angle to the existing wall, you will also get 90 degrees for the new wall AND you will be able to sleep superbly.

So how did it go? Yeah, they differed by 2 mm (1/16″) and that’s no problem. Though I don’t know if it really helped with the sleeping.

If they in the unlikely event hadn’t been all square, I would have had to settle with making the left wall square to the back wall and then making sure the front edge is atleast the correct width where the doors and sliding rails will connect to the wall.

I have also made sure all walls are perfectly vertical. This is basically essential. Even though the doors are adjustable for a little bit of tilt, it would require to always have the same door against that wall. More on this matter when we come so far as installing the doors.

Now I picked up some material and hoped to get going today but I got started a bit late.

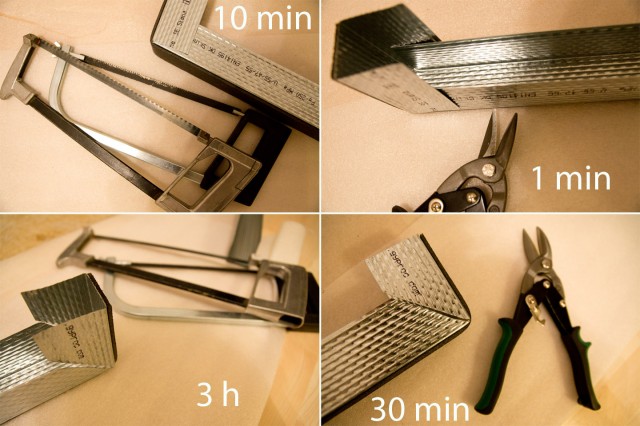

And just a tip if you are ever going to build something with steel rails – get a suitable cutter. I didn’t, so I had to try my hacksaw. It’s not a good idea. It’s harder than you might think and makes a lot of chips and is too noisy to do in the middle of the night. So that’s why I’m starting up this blog tonight instead.

I only have a few cuts to make though so I will probably do them withouth a steel scissor/(shears?) anyways. I just wish somebody could clean up the metal dust after me.

Until next time. Cheers!